Direct vs. Indirect Procurement – Process & Examples

No matter the business size, having a steady and well-thought-out supply of production materials is crucial for success. If material procurement isn’t planned properly, it can lead to expensive production downtimes and unnecessary costs from buying too much. In this article, we’ll explore how different companies use direct and indirect methods to make their business processes more efficient.

Understanding Direct and Indirect Procurement

Depending on the business model involved, supply chain professionals can take one of two approaches to procure the materials they require in their daily operations.

Procurement can either be direct (focused on purchasing materials to achieve a profitable outcome) or indirect, where materials, services, and supplies paid for are used to maintain the business but do not necessarily contribute to overall profitability.

In reality, most businesses will likely need a combination of both procurement strategies mentioned above to operate effectively. However, it’s crucial for every business operator to grasp the key differences between these methods in order to strike the right balance in their real-world business processes.

Direct vs. Indirect Procurement – Key Differences

There are some fundamental differences between direct and indirect procurement. These differences are outlined below.

- Supplier and purchasing team relationship

- The pattern of inventory management

- Company procurement policies/team structure

Supplier and Purchasing Team Relationship

With direct procurement, the company’s procurement team works closely with material suppliers to establish a lasting relationship. This ongoing process involves clear communication about delivery schedules and material needs.

Indirect procurement is more transactional, where business purchasing units focus on comparing vendors and selecting the one with the most competitive and cost-effective delivery proposals, without necessarily prioritizing a long-term relationship with suppliers.

The Pattern of Inventory Management

Direct procurement entails a proactive and streamlined approach to material purchasing. The team overseeing a direct purchase system consistently updates inventory, ensuring essential components are readily available as needed.

On the other hand, indirect procurement involves ordering materials only when there’s a demand. While this approach eliminates redundancies, it may lead to production delays due to the potential unavailability of necessary raw materials.

Company Procurement Policies/Team Structure

Companies operating direct procurement systems typically have centralized purchasing teams dedicated to specific supply needs. Consequently, they have more rigid budgets and procurement targets.

Indirect procurement is often more flexible and decentralized, with spending done on variable material demands. Spending is often unpredictable, and purchase redundancies are more likely to occur.

Direct Procurement Process

The direct procurement process simply involves purchasing raw materials, components, and services from vendors or suppliers to generate a net profit. A business running a direct procurement setup typically has a dedicated purchasing team that liaises with a chosen vendor to supply the necessary items. The in-house team usually keeps an inventory of materials, predicts deficits, and communicates with their vendors to supply the required items.

Direct Procurement Examples

Some common examples of direct procurement in the everyday business world include the following:

- Purchase of mechanical components for production equipment

- Supply and installation of industrial machinery

- Provision of raw materials needed for manufacturing finished goods

- Outsourcing and subcontracting labor/manpower in construction

Challenges of Direct Procurement

Although direct procurement is an efficient approach to supply acquisition, it is based on the assumption that the business model remains profitable. If there are any issues in this tightly wound supply, utilization, and profitability cycle, direct procurement becomes an impractical business approach.

Indirect Procurement Process

A common misconception is that indirect procurement is not directly involved in creating profits for a business but is nonetheless critical to its continued survival. An indirect procurement process allows the purchase of items used in running day-to-day activities. This process is typically decentralized and runs on a departmental level, in which each team or unit pulls resources for their supplies as demands surface.

Indirect Procurement Examples

Indirect procurement activities include the following examples:

- Purchase of MRO (maintenance, repair, and operation) consumables used during the manufacturing process and to maintain plant operations and equipment maintenance parts.

- Freight and logistics

- Travel

- Purchase of office furniture, stationery, and other supplies

- Payments on utilities (heating, electricity, water)

- Employee improvement/training costs

- Fees for external consultants and services

- Marketing and advertising expenses

- Fees for purchasing and maintaining business hardware (computers, printers, phones) and software (computer programs, archiving, and storage systems)

Challenges of Indirect Procurement

Due to its largely decentralized nature, indirect procurement is more chaotic than a direct process of obtaining materials. As a result, the traditional indirect process is more prone to surpluses and redundancies as each team within the company operates separate procurement budgets while many required materials are similar. This lack of centrally organized material demand and flow may negatively impact the overall costs of running the business.

Discover DXPs Procurement Management Solutions

At DXP, we’re dedicated to offering top-notch procurement management services tailored to your business. We know every business is unique, so we approach each client with the best strategy to improve their processes.

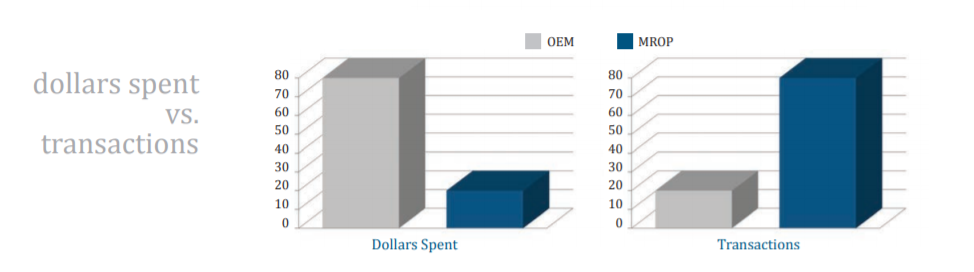

Let us guide you in transforming your indirect processes from a hassle to a profit-making streamlined system by focusing on cost reduction. DXP excels in reimagining the indirect MRO procurement process, turning it into a competitive advantage for industrial customers.

If you’re seeking efficient and cost-effective material procurement, DXP is the right partner for you. Contact us online today!