INNOVATIVE

PUMPING SOLUTIONS

for Your Application

Design, Engineering, Manufacturing to fit your needs.

Contact Sales

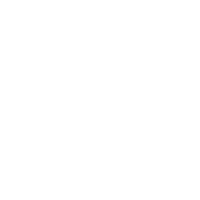

PUMPING

With over 100 years in the rotating equipment industry, DXP can proudly assure our customers we can handle anything they might need. Whether or not you purchased the equipment from us, we service and repair all makes and models—big or small—all across the United States and Canada.

MEASUREMENT

DXP is your total solution provider of wellhead and midstream measurement, along with crude oil and produced water products, instrumentation and filtration products.

PROCESS CONTROLS & AUTOMATION

Advanced control systems allow monitoring, controlling, and automation of multiple processes.

REMANUFACTURING

Hydraulically re-rated from surplus or used industrial pumps and components into a new product.

LOCAL SERVICE & REPAIR

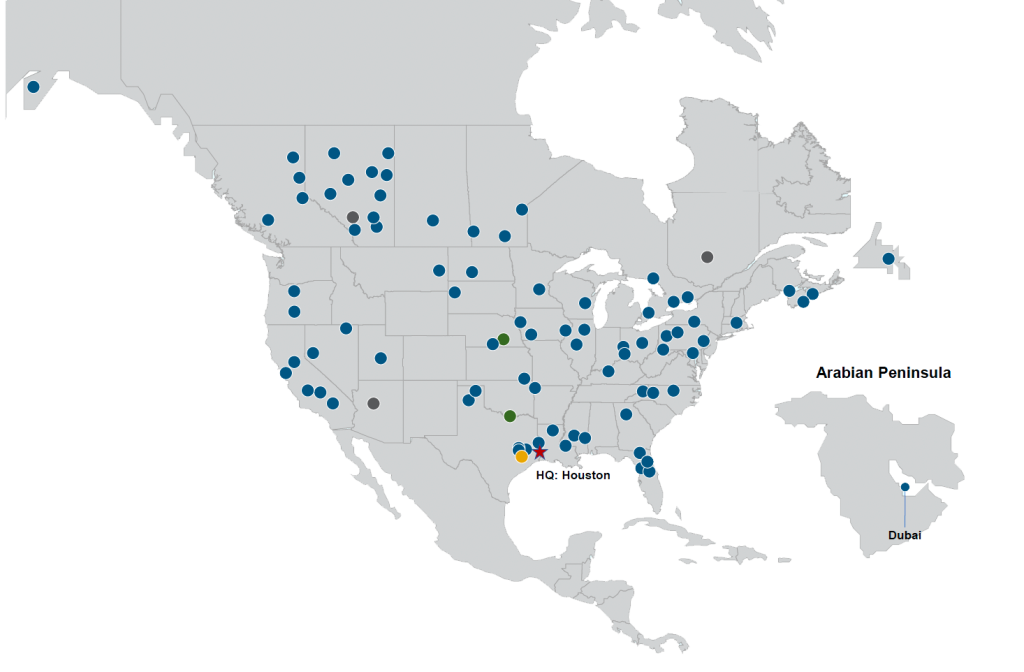

No matter where you are in North America, our repair technicians and specialists can respond to your service needs 24 hours a day, 365 days a year for in-house and field service calls.

About/History

DXP Innovative Pumping Solutions is a leading provider of pumping solutions with a rich history, a diverse product portfolio, and a commitment to customization, innovation, and sustainability. Serving a wide array of industries our experts have deep industry knowledge that ensures they understand the specific challenges and needs of each sector. Our Innovative Pumping Solutions play a crucial role in ensuring the efficient and reliable handling of fluids across various industries and applications.

Markets

Founded in 1908, DXP brings over a century of rotating equipment and packing expertise to a multitude of markets. We are your partner for the designing, manufacturing, packaging and maintenance of rotating, measurement and process equipment. Combining unparalleled engineering depth, the most extensive network of service locations in North America, and the highest level of technical expertise in industrial distribution, your DXP team is able to serve the following markets:

- Upstream Oil & Gas Industry

- Midstream Oil & Gas Industry

- Lng/Downstream Industry

- Environmental/Air Quality Industry

- Biofuel Industry

- Renewable Energy

- Carbon Capture, Usage & Storage (CCUS)

Capabilities

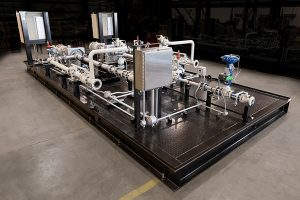

Project Management

Each Project Management Group consists of a dedicated Project Manager, Project Engineer and Design Team to manage each project from start to finish.

Engineering & Design

Having a fully staffed detailed engineering and design team at IPS is one of DXP’s greatest value adds. We staff mechanical, process, electrical, instrumentation, and control engineers at our Katy, Texas facility. For design, DXP uses the latest SOLIDWORKS software to generate 3D models of each package. These models minimize equipment interference during assembly and maximize safety for the field operations personnel.

Process Simulation

DXP utilizes Aspen Plus Process Stimulation Software for conceptual design, optimization, and performance modeling of DXP’s proposed solutions to customer requirements.

Automation

DXP knows that the proper integration of automation and controls with packaged mechanical equipment is important. DXP’s Automation & Controls team understands the process requirements to design and supply the best controls for the job. From the simplest functions to PLC’s incorporating control functions outside DXP supplied packaged equipment, automation is a large part of DXP’s added value.

Aftermarket/Service Parts Service

Our dedicated Aftermarket Group provides onsite factory training and commissioning start support, as well as operator training. Our parts department offers spare and replacement parts throughout the service life of our equipment and our service center locations offer local MRO support throughout North America.

Quality Control/Quality Assurance

Our IPS Design & Manufacturing facility has been ISO-9001 certified since 2012 and completed our ISO 9001:2015 certification by DAS in 2020. In keeping with our dedication to the highest quality standards, we were re-certified in 2023.

Engineering & Design

DXP Innovative Pumping Solutions utilizes the most up-to-date technology to meet the demands of its global customer base. Using 3D mechanical design software, DXP provides a complete design solution with verification to meet the customer needs.

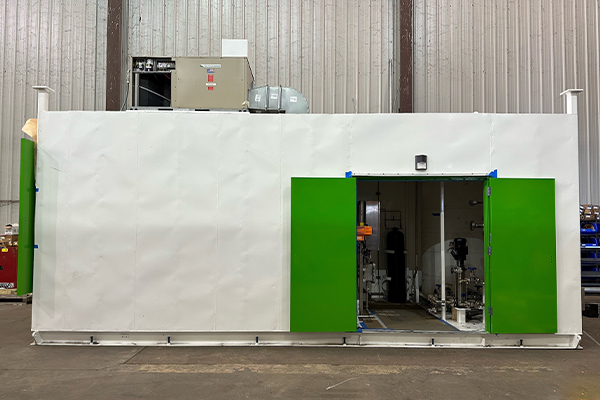

DXP Fabrication Facility

Innovative Pumping Solutions (IPS) headquarters are located in Katy, Texas. IPS’s fabrication facility spans 110,000 square feet and is located in a thirty-acre lot with prime access to major roadways. In addition to design and engineering, at this facility we perform skid and piping fabrication, assembly, paint, electrical and controls integration as well as final testing (all in-house). DXP maintains the highest quality standards for manufacturing of pumping, measurement, and process equipment.

Service and Support

Comprehensive footprint providing access and coverage for key markets

- 156 Service Centers

- 16 Fabrication Centers

- 6 Manufacturing & Remanufacturing

- 4 Wastewater Locations

- 4 Ballistic Distribution Centers

- 1 Customer First Centers

PRODUCTS: Pumping

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat. Duis aute irure dolor in reprehenderit in voluptate velit esse cillum dolore eu fugiat nulla pariatur. Excepteur sint occaecat cupidatat non proident, sunt in culpa qui officia deserunt mollit anim id est laborum.