Centrifugal Pumps: Parts, Types & Working Principle

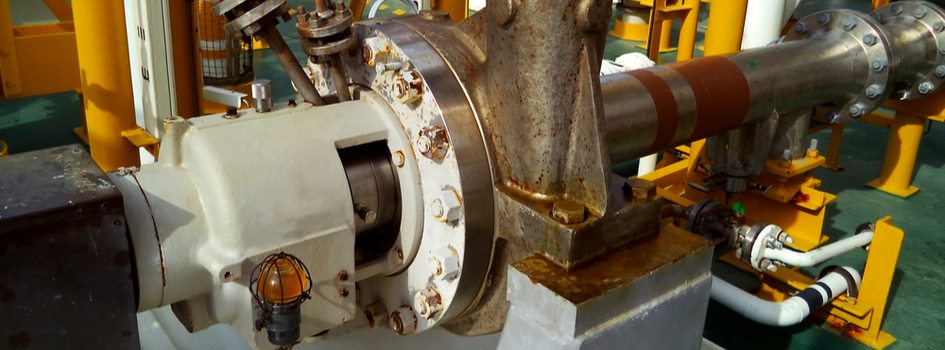

Ever wondered how centrifugal pumps work and what exactly they do in industrial settings? They play an important role in various industries, from manufacturing to wastewater treatment. Understanding how centrifugal pumps work is critical to choosing the right configuration for any given industrial setup.

What Are Industrial Centrifugal Pumps?

Centrifugal pumps are pressure-producing mechanical devices that transfer kinetic energy generated from centrifugal force to hydrodynamic energy, resulting in the flow of all kinds of fluids that are required for industrial and municipal processes.

How Do Centrifugal Pumps Work?

Centrifugal pumps operate by using centrifugal force to convert kinetic energy into hydrodynamic energy, facilitating the flow of various industrial fluids. Here’s how they work:

- Fluid is supplied through a nozzle and directed at an impeller within the pump system.

- The impeller’s rotation generates kinetic energy, which is transferred to the fluid.

- The energized fluid enters a volute casing or diffuser, where it slows down and its pressure increases.

Types of Centrifugal Pump Systems

Centrifugal pumps come in varied configurations which are suited for different industrial applications. The most popular variants are listed below.

- Axial and mixed flow vertical and horizontal centrifugal pumps

- Radial flow vertical and horizontal centrifugal pumps

- Electric, engine and hydraulically driven centrifugal pumps

- Single and multistage centrifugal pumps

- Vertical turbine and vertical sump centrifugal pumps

- Submersible centrifugal pumps

ANSI vs. API Pumps

Centrifugal pumps are a staple in mechanical pumping systems across the USA, but did you know they come in different standards? The two main standards you’ll encounter are set by the American National Standards Institute (ANSI) and the American Petroleum Institute (API).

ANSI Pumps: These are top-notch single-stage centrifugal pumps known for low maintenance and high efficiency. Originally designed for the chemical industry, they now serve various industrial markets due to their standardized designs and internal specifications.

API Pumps: If you need pumps for high-pressure and high-temperature applications in oil and gas, API pumps are the go-to. They meet strict specifications and come in both single and multistage configurations.

Both ANSI and API pumps are radial centrifugal pumps offered in various sizes, metallurgies, and configurations to suit different industrial needs.

Common Applications of Centrifugal Pumps

Some key industrial applications that benefit from the use of centrifugal pumps are outlined below:

- Commercial food processing

- Alcoholic beverage manufacturing

- Chemical product synthesis

- Residential waterworks

- Oil and gas recovery

- Fire protection systems

- Sewage/slurry disposal systems

Centrifugal Pump Parts

To operate properly, a standard centrifugal pump relies on several key components:

- An impeller

- Diffuser or volute casing

- Shaft and shaft sleeves

- Bearings

- Mechanical seals, Packing and Casing Cover

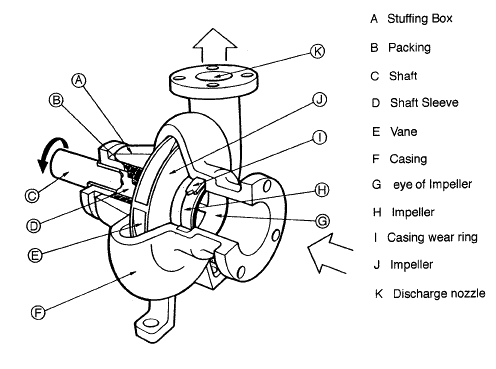

Impeller

The impeller is attached to the shaft and spins at the same speed as the shaft, powered by a motor, engine, or hydraulic unit. As fluid enters the impeller’s eye, it passes through the vanes, gaining velocity and kinetic energy. By the time the fluid exits the impeller and enters the casing, its velocity matches the impeller’s rotational speed.

Diffuser or Volute Casing

The diffuser or volute casing is responsible for containing the fluid and generating fluid pressure. It slows down the fluid’s velocity upon entry, converting velocity into pressure.

Shaft and Shaft Sleeves

The shaft is the central part of the pump’s rotor system. It supports the impellers, mechanical seal, and bearings. The shaft provides a rigid framework for pump operations.

Bearings

Bearings support the shaft and other rotating components within the pump’s housing. They absorb radial and axial forces during pump operation, maintaining shaft alignment for peak efficiency and reliability. Types of bearings used include anti-friction bearings, pivoted-shoe thrust bearings, and sleeve bearings.

Mechanical Seals

Mechanical seals or packings prevent the pumped fluid from leaking along the rotating shaft. They are housed within the casing cover at the back of the pump casing. The type of seal used depends on factors like the process fluid, operational temperature, and pressure.

Centrifugal Pump Diagram

The diagram above shows the essential components of any standard centrifugal pump system.

Additional Resources

Exploring all aspects of centrifugal pumps is a deep dive beyond one article. For those seeking more information on this essential industrial equipment, here are some additional resources:

- Different Types of Centrifugal Pumps and Their Applications

- How to Read a Pump Curve for Centrifugal Pumps

- Centrifugal Pump Maintenance Procedures for Industrial Pumps

These DXP articles offer valuable insights into operating industrial centrifugal pump systems.

Partnering with a Centrifugal Pump Supplier

Selecting the right centrifugal pump type is obviously #1, but choosing a process pump supplier who understands your specific needs is just as important. At DXP, we provide top-notch centrifugal pump solutions for various industries. Let’s optimize your pumping process together!

Contact us today to learn more about how DXP can help.