3 Tips for Better Bearing Maintenance

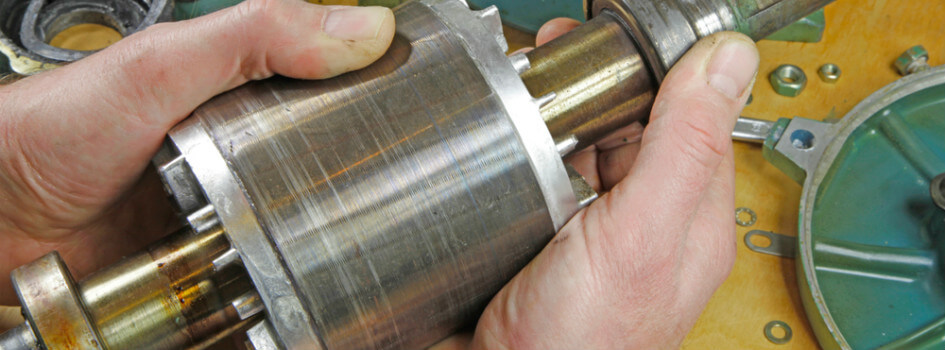

Maintaining the bearings in rotating equipment is an essential part of keeping machines running smoothly and efficiently. By following bearing maintenance best practices, a business can extend the life of its equipment, reduce downtime from avoidable failures, and improve safety.

3 Tips on How to Maintain Bearings

Here are three tips that every operator of rotating equipment should follow.

1. Know Why Bearings Fail

An important part of understanding how to avoid problems is to know what problems to look for. Bearings can fail for many reasons, including:

- An incorrect installation, which can result from improper seating of the bearing relative to the shaft or housing, or not following mounting guidelines.

- Misalignment of the bearing or shaft, which can cause damaging vibrations and friction.

- Inadequate or damaged seals.

- Dirty, improper, or insufficient lubricants.

- Vibration passing from other parts of the equipment to the bearing.

- Stray electric currents running through the bearing.

2. Follow a Lubrication Schedule

Bearings must be lubricated with the correct material to operate at optimal efficiency. Lubricants do important work inside a bearing, serving as a friction-free barrier between the bearing’s parts, preventing wear, reducing heat, and preventing dirt and other contaminants from getting into the bearing’s sensitive components.

Grease lubricants provide bearings with a seal against contamination, while oil lubricants control a bearing’s thermal characteristics. The correct lubricant is determined by your bearing selection and its application.

3. Check for Misalignment

Every bearing has a certain alignment tolerance past which it will suffer damage. Misalignment problems in a bearing can be an indication of problems elsewhere in a machine. Verifying alignment should be a core part of any bearing maintenance routine. Rotating equipment vibration analysis can typically identify symptoms of misalignment before they cause major issues.

Better Bearing Solutions with DXP

DXP provides comprehensive bearing sales and support. From industrial bearing supply and installation to ongoing maintenance, DXP helps customers get the most from their rotating equipment.

Contact DXP today to find out how we can help your business solve its bearings challenges.