The Ultimate Guide to Inventory Management in Supply Chain

Your inventory management processes are a vital part of the supply chain process. Inventory management in supply chains ensures that companies maintain the right amount of stock to fulfill customer demand.

This guide will introduce you to the best practices in supply chain management and show you how they improve the world of business.

Why is Inventory Management Important?

Supply chain inventory management impacts virtually every area of business. Because inventory represents a tangible company asset, companies can manage their revenue by managing their MRO inventory. And perhaps most importantly, inventory management can ensure greater customer satisfaction by meeting demand with speed and efficiency.

Proper inventory management in supply chains can improve organizational efficiency by:

- Saving money by stocking only what you need

- Improving cash flow by stocking only what sells

- Satisfying customers by minimizing delays in inventory

Simply put, inventory management can reduce overhead costs while keeping your customers happy…which is good news for businesses of any industry.

Overcoming Inventory Management Challenges

Businesses can improve efficiency by overcoming all types of inventory management challenges, such as:

- Stocking too much unsold inventory

- Lacking inventory to fulfill orders

- Failing to keep track of inventory items and quantities

- Relying on manual processes that introduce errors

- Changing customer demands

- Utilizing warehouse space efficiently

You can overcome these challenges by implementing today’s best practices in supply chain inventory management.

Inventory Segmentation

Segmentation is where inventory becomes easier to manage.

ABC by annual spend

A small number of items usually account for most of the spend. ABC grouping helps focus attention, even though it is not perfect.

XYZ by demand pattern

Stable items behave very differently from intermittent ones. Supply chain planning breaks down when unpredictable items are treated like steady movers.

Consequence based grouping for MRO

Adding a simple consequence tag helps guide stocking decisions when demand data is limited.

How to Improve Inventory Management in the Supply Chain

Few things are as important to a business as inventory management. Improving your inventory processes can positively affect your overall MRO supply chain and keep your customers happy. Here are some of today’s best practices.

Use an Effective Inventory Management System

An inventory management system is the tool a team uses to track what is on hand, what is on order, and what is being used. At a basic level, it records receipts and issues. At a more useful level, it supports replenishment decisions and helps keep inventory behavior predictable.

Some teams still rely on spreadsheets. That can work for small operations with limited items and few locations. But once volume grows, spreadsheets start to fail us, and by the time a problem shows up, it is already old. Most modern systems handle:

- On hand balances by location and bin

- Receipts, issues, returns, adjustments

- Supplier and lead time records

- Reorder points or min/max levels

- Basic approval and alert workflows

The system does not make decisions for you. Rather, it enforces consistency. If parameters are reasonable and transactions are timely, the system helps inventory behave the way it should. If data is sloppy, the system will surface that quickly.

One practical note: storeroom management software only works if people use them at the point of work. If spare parts are issued after the job, or not at all, accuracy erodes fast. Make transactions part of the process, not an afterthought.

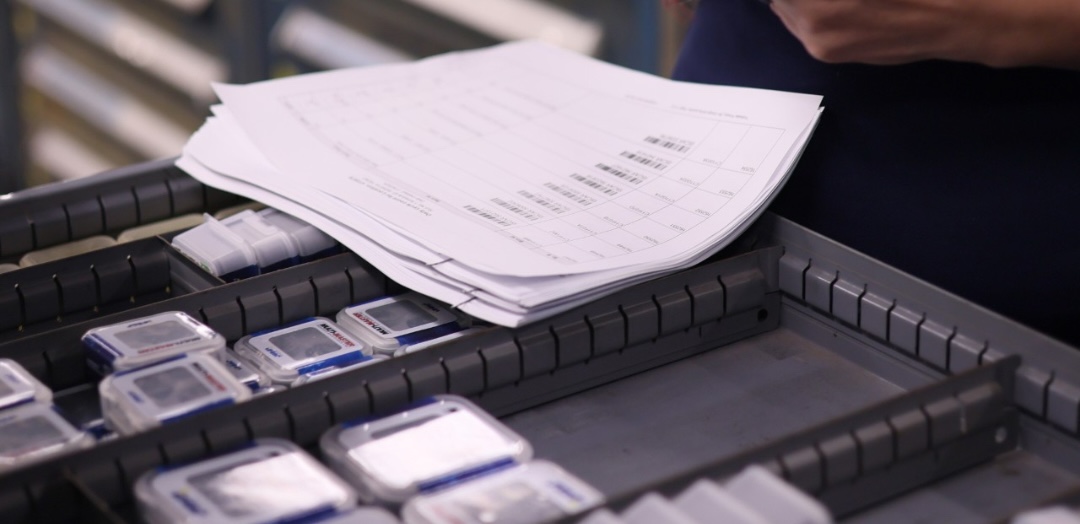

Keep Detailed Product Records

Inventory turnover is key to maintaining supply chain management. Keeping detailed records of the items in your inventory will help you evaluate what’s working (or selling) and what’s not. Track information such as:

- Product names

- SKUs

- Barcode data

- Lot numbers

- Supplier details

If you introduce the right technology, you can track this data through a centralized system for better efficiency and transparency.

Tracking supply chain metrics like inventory turnover, days inventory outstanding (DIO), and fill rate gives a clearer picture of how inventory is actually performing. These numbers usually reveal problems faster than gut instinct.

Regularly Audit Your Inventory

How often are you moving inventory in and out of your warehouse? Regular audits can help you better understand your current needs or where you’ve made the mistake of overstocking.

Some companies audit their inventory systems annually, while others do so monthly or even weekly. The right inventory management system can give you end-to-end transparency, making it easier to take stock of your current inventory.

Many supply chain operations now rely on regular cycle counts instead of annual audits. Smaller, more frequent checks tend to catch issues earlier and cause less disruption.

Maintain a Relationship with Your Suppliers

Supplier reliability has a direct impact on inventory performance. By maintaining regular communication with your vendors and suppliers, you’ll be notified when items are out of stock or when certain products become available.

Given the recent supply chain management challenges, many companies are finding it helpful to build relationships with multiple vendors. Purchasing from local suppliers can eliminate some of the challenges and costs associated with purchasing from long distance (or even international) companies.

Tracking supplier performance, such as lead times and order accuracy, helps reduce downtime and last minute purchases that usually cost more.

Since COVID and ongoing geopolitical disruptions, many organizations have reduced reliance on single suppliers by diversifying sources or nearshoring critical inventory. This approach improves resilience but often requires tighter coordination and better data.

Integrate Technology Where Possible

Your supply chain can benefit from digital supply chain inventory management tools. The right platform can offer benefits that include:

- Real time data of your current inventory

- End-to-end visibility of your entire supply chain performance

- A centralized hub to manage incoming and outgoing orders

- Integration with other software tools (such as accounting)

- Automation of key processes

Cloud based platforms make these integrations easier by connecting inventory, procurement and logistics systems through shared data and APIs. This reduces manual handoffs between systems and keeps information consistent across teams.

These systems do not replace decision making, but they do remove delays and manual errors that slow teams down. When inventory data updates automatically, planners and maintenance teams can react sooner instead of working off outdated reports.

In some environments, IoT devices and sensors are used to track inventory movement, usage, or condition in real time. This is especially useful for high value, regulated, or maintenance-critical items that require traceability.

Many platforms now provide real time inventory visibility across multiple locations. This makes it easier for procurement, maintenance, and operations teams to stay aligned. Not only will you eliminate the errors that come from manual data entry but you’ll empower your supply chain teams to manage inventory and orders from a single system.

Remember, inventory management is ongoing.

Inventory management never finishes. Demand, suppliers, and operations keep changing.

Programs that hold up over time keep data clean, enforce transactions, and review parameters on a schedule. It’s not glamorous work, but it is the work that keeps inventory usable.

Discover DXP’s Inventory Management Solutions

Effective inventory management in supply chains is of strategic importance for any business. DXP can help. Our smart solutions can streamline your supply chain management process and give you better visibility and control over your inventory and orders.

Call (936) 261-7736 for more information about our SmartSolutions and other supply chain services.