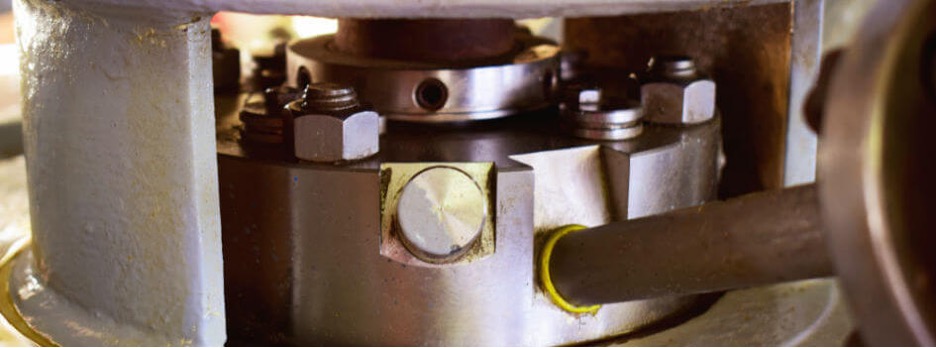

Mechanical sealing systems are crucial in achieving energy savings in various industrial processes. These components are designed to prevent leaks, ensuring that valuable fluids and gases stay contained within machinery… Read more »

Mechanical sealing systems are crucial in achieving energy savings in various industrial processes. These components are designed to prevent leaks, ensuring that valuable fluids and gases stay contained within machinery… Read more »

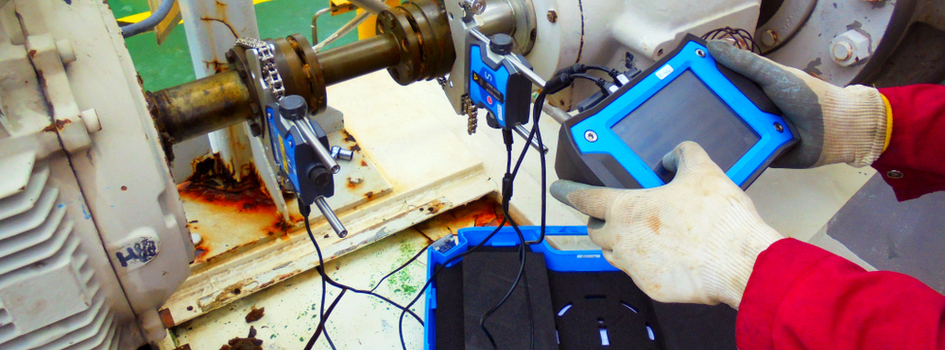

As industries continue to embrace digital transformation, equipment health monitoring devices will play a big role in shaping the future of maintenance and asset management. Keep reading to learn more…. Read more »

As seasoned pump experts with years of experience in the field, DXP understands the importance of proper pump testing protocols. Ensuring that industrial pumps function efficiently is important for maintaining… Read more »

In our ultra-competitive marketplace, organizations across virtually all industries constantly search for ways to improve margins, optimize productivity, and protect business continuity. This drive has become particularly important for entities… Read more »

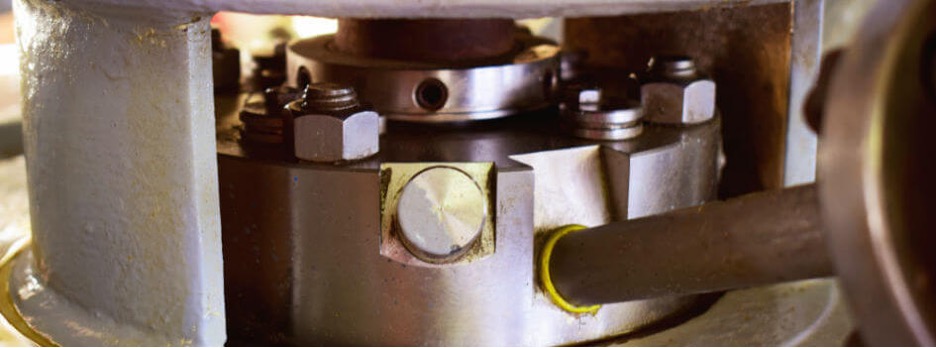

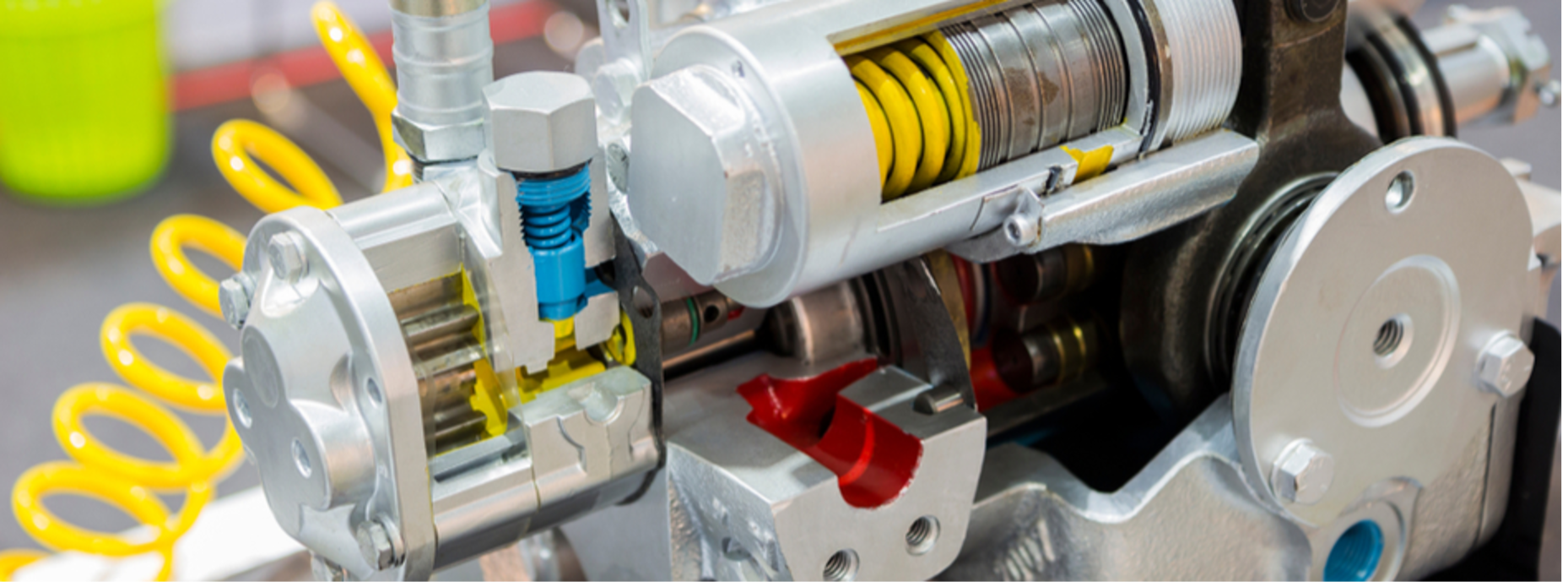

We’ve covered the differences between centrifugal and positive displacement pumps, but how much do you really know about the latter? Let’s dive deeper into the world of positive displacement pumps… Read more »

During initial exploration, natural gas formation pressures are sufficient to sustain maximal output. However, these pressures will eventually dwindle, resulting in diminished productivity. In these cases, enhanced oil recovery techniques… Read more »

Reading pump performance curves is an essential skill when sizing pumps for efficient and reliable operation in various applications. It is also useful when troubleshooting or verifying that the pump… Read more »

Centrifugal pumps form an integral part of many industrial processes. These machines are commonly used in the chemical transportation and processing industry to channel process fluids through various manufacturing systems…. Read more »

As the industrial revolution 4.0 continues to advance the adoption of web-connected devices to production equipment is becoming more common. The ability to have proactive early warning of potential machine… Read more »

Optimizing the return on investment in equipment is an important component of an industrial operation’s long-term financial performance. As machines age, their associated costs tend to grow. It can be… Read more »