A Quick Guide to Linear Bearings, Guides, and Actuators

Getting something to move in a straight line and keep doing it day after day takes more than luck. CNC systems, packaging machines, and robotics all rely on linear motion components to make that happen. Bearings, guides, and actuators each do their part…the bearing keeps friction low, the guide keeps everything aligned, and the actuator supplies the push or pull. Keep reading to learn more about the different types of linear bearings and more.

Linear Bearings

A linear bearing reduces friction between moving parts to support motion along one axis. Common in 3D printers, automation systems, and machining assemblies, they fall into two categories: rolling linear bearings and plain linear bearings.

Check out our Bearing Selection Guide for more help.

Rolling Linear Bearings

Rolling bearings use balls or rollers between the moving parts. That’s what cuts down the friction and keeps motion predictable. The contact angle between the rolling element and the rail changes how much load it can handle…larger angles help with vertical load but reduce side stability.

- Ball Bushing Bearings – Ball bushings use recirculating steel balls along hardened shafts for low resistance and repeatable accuracy. Used in CNC and precision automation. Seals or clean environments are recommended to avoid contamination.

- Roller Bearings – Roller bearings use small cylindrical rollers that spread the load over a bigger area. That lets them carry heavier loads at higher speeds. You’ll see these on heavy machinery tables and linear transfer systems. Lubrication and proper alignment make or break their lifespan.

Plain Linear Bearings

Plain bearings don’t use balls or rollers. They slide on a film of material, often bronze, polymer, or a composite. They can handle dirty, vibrating environments better than rolling bearings, though they have more drag.

- Sleeve Bearings – Simple and durable, sleeve bearings provide motion with minimal maintenance in dirty or harsh environments.

- Self-Lubricating Bearings – These have lubricant built into the material. No need for regular greasing. They’re good in places you can’t reach often for maintenance.

Tip: When picking a bearing, think about load, travel speed, and environment. A bearing that’s too small or not suited to the setup wears out fast and loses accuracy.

Linear Guides

Linear guides restrict motion to one axis and maintain alignment in mechanical systems. They are divided into contact and contactless types.

Contact Linear Guides

Contact guides use rolling or sliding contact between the rail and the block.

- Roller Bearing Guides: These handle dust and misalignment better than most. Bearing maintenance is low, but they don’t like high speeds or precise positioning work.

- Ball Bearing Guides: Recirculating ball blocks offer high rigidity and precision. Require accurate alignment and lubrication.

- Friction Guides: Simple and low cost. Operate dry but are unsuitable for high-speed operation.

Contactless Guides

Contactless guides remove mechanical contact entirely. They’re expensive but wear-free.

- Air Bearings: The block floats on a film of air. Friction is nearly zero. Needs a perfectly flat surface and stable air pressure.

- Hydrostatic Guides: Separate components with an oil film for precise motion. Used in machine tools.

- Electromagnetic Guides: Use magnetic levitation for cleanroom and vacuum applications. High cost and complex control.

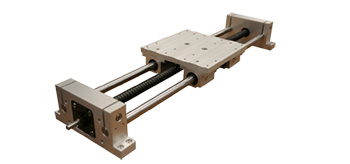

Linear Actuators

The actuator is what moves the load. It converts rotary motion into linear motion. DXP offers ball rail, ball screw, electromechanical, and mechanical actuators. Each suits different loads and precision needs.

Electromechanical Actuators

These can be hand-driven or motor-driven. They include belt, screw, and rack-and-pinion types. Used in robotics, automation, and medical systems where control matters. They’re quiet, clean, and easy to integrate with control systems, though they can’t push as hard as hydraulic setups.

- Belt-Driven: High speed, low load, long stroke. Require proper belt tensioning.

- Lead Screw-Driven: High precision, short travel (under 5 ft). Suitable for clean, accurate setups.

- Ball Screw-Driven: Higher load and accuracy, used in CNC and robotics. Require lubrication.

- Rack and Pinion: High load and durability for heavy-duty or high-temperature applications.

Hydraulic Actuators

Use pressurized fluid to move a piston. Deliver high force and long life but need maintenance to prevent leaks.

Pneumatic Actuators

Run on compressed air. Light, simple, and reliable. Good for packaging and material handling. Not as accurate but easy to maintain.

Piezoelectric Actuators

Use piezo materials that expand under voltage for micron-scale motion. Used in semiconductor, lab, and medical applications.

System Interaction

In a motion system, the actuator provides force, the guide keeps it straight, and the bearing reduces friction. If one is out of alignment, accuracy drops fast. Most motion issues trace back to mechanical setup, not electronics. Always check alignment, preload, and lubrication before blaming the controls.

Browse DXP’s Linear Motion Solutions

DXP supplies linear motion products, guides, and actuators from trusted manufacturers. Our bearings and power transmission team specializes in matching components correctly from the start…saving you time and reducing downtime later on.Contact DXP today to learn more.