Inventory Vending Machines: A Simple Solution

Inventory control tends to fall apart when gear sits on open shelves. People grab what they need, someone forgets to log usage, and the system slowly drifts off target. That’s why many operations use an inventory vending machine.

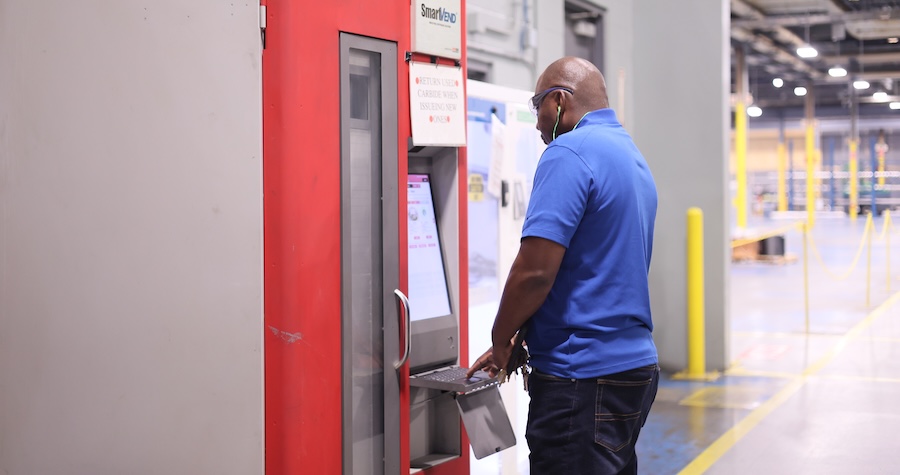

These units aren’t anything extravagant. Larger facilities often treat them as part of broader industrial vending machines programs that sit close to the actual work area. Think of a rugged industrial cabinet with automated dispensing and tracking built in. You load it with PPE, inserts, bits, batteries, cutters, chemicals, and anything else your team burns through every week. Workers badge in, take the item, and the system records it. Simple as that!

How an Inventory Vending Machine Works

With these machines, you’re no longer guessing or chasing people. It’s an easy process that runs the same way every time! An inventory vending machine is built around a simple loop:

- Identify the user – Badge, PIN, or shop login. The system needs to know who’s pulling what.

- Select the item – Either a coil, locker, drawer, or bin opens.

- Dispense and record – Once the drawer cycles or the door unlocks, the machine logs the transaction.

- Update stock data – Counts adjust in real time.

- Trigger replenishment – When a part runs low, the system flags it for restock.

Under the hood, systems may use barcode scanning, RFID, weight‑based scales for high‑volume items like gloves or batteries, or motion‑sensed recording. In many shops, these features support vendor managed inventory workflows without changing how crews pull parts. Some units also support biometric access and electronic MSDS access.

What You Can Store

These machines handle consumables that disappear fastest on a jobsite or in a shop:

- PPE

- Carbide inserts

- End mills

- Abrasives

- Batteries

- Adhesives and sealants

- Cleaning chemicals

- Welding consumables

- Electrical fittings

Units come in coils, lockers, lift drawers, or hybrid formats. In some operations, these serve as inventory management vending machines that keep high‑turn parts controlled without slowing production. Some models handle fragile items, boxed consumables ranging from small cartons up to large cases, controlled chemical storage, and charging bays for radios, laptops, and flashlights. Shops usually mix and match depending on part size, turnover, and any handling requirements.

Why Shops Use Inventory Vending Machines – Top 10 Reasons

An inventory vending machine cuts down wasted time and missing parts while keeping consumables organized and traceable. For most shops, that’s enough reason to put one in service! But for the sake of this article, here are 10 more reasons:

1. Reduced waste

When items are tracked by user, consumption tends to stabilize. People grab what they need, not handfuls “for later.”

2. Faster access

The machine sits near the work area. No walking to a crib window or waiting on someone to hand out supplies.

3. Better stock accuracy

Every pull logs instantly! That means no chasing down missing counts and no surprise outages.

4. Cleaner audits

Supervisors can see usage by department/shift/person. It’s easier to spot unusual patterns.

5. Tighter part control

You can limit item types by user group. For example, only welders can pull MIG tips, or only maintenance can pull arc-rated gloves. Some systems also support consumption limits.

6. Better visibility

Reporting tools turn raw usage into data supervisors can act on. Some machines track gauges and calibration intervals automatically.

7. Automated or assisted ordering

Certain setups support automated ordering or point‑of‑use request tools, cutting down on stockouts and manual purchasing.

8. Advanced tracking & security

Some systems use motion‑sensing cameras, full‑cabinet recording, and event replay to monitor activity. Others support facial recognition, prox‑badge authentication, tamper‑proof housings, and heartbeat diagnostics.

9. Tool & equipment tracking

Check‑in/check‑out workflows allow shops to manage gauges, durable tools, radios, and laptops while recording usage history and calibration or expiration dates.

10. Safer chemical & flammable storage

Certain cabinets include spill‑control bins, chemical‑rated compartments, and controlled‑access storage for solvents and flammables. Some units can handle over 100 SKUs in a footprint similar to a 60‑gallon storage setup.

Where They Fit Best

An inventory vending machine works well anywhere consumables move quickly:

- Fabrication shops

- Machine shops

- Maintenance departments

- Oilfield tool trailers

- Warehouse repair areas

- Utility fleets

- Chemical plants

The common thread is frequent, repetitive use. For many plants, these systems help with inventory cost reduction by cutting waste and tightening daily part usage. These environments burn through parts and need a clean way to track them.

Learn more about DXP’s vending and scanning solutions.

Setup / Daily Use

Putting a machine in service isn’t complicated:

- Decide the consumables you want controlled.

- Load them into coils, lockers, drawers, or bins.

- Assign access groups.

- Tie the unit into your ERP/purchasing system.

- Train the crew.

After that, the system runs on its own. Remote equipment monitoring and configuration tools make supply chain transparency easier when multiple crews pull from the same stock. Some operations use runner systems or automated ordering.

Partner With DXP for Better Vending Control

DXP has supported industrial operations for decades, and vending systems are one of the areas where that experience pays off. Our team helps crews figure out what to stock, how to configure each cabinet, and how the software should be set up so the system actually fits the way your facility works…not the other way around.

We support everything from planning and installation to training, replenishment, remote monitoring, reporting setup, and ongoing adjustments as your usage patterns change. If you want a program that stays reliable without adding work to your crew, let DXP run the entire operation for you!

Call (936) 261-7736 for more information about our SmartSolutions and other supply chain services.