Industrial Clamp Guide: Different Types of Clamping Systems

Believe it or not, machining precision starts with how a part is held. Workholding clamps are used to keep a workpiece fixed during cutting, welding, or assembly so forces don’t shift the setup mid-process.

What Are Clamping Systems?

Simply put, a clamp applies holding force to resist movement. That may be a screw-driven C-clamp on a bench, a toggle clamp in a fixture, or a hydraulic unit tied into a CNC machine. Other common devices that fall under workholding include chuck clamps, lathe chucks, and vise jaws. Each serves the same role: apply consistent pressure so machining forces are absorbed by the fixture instead of the part.

Shop tip: “If the clamp slips, accuracy is gone before the tool touches metal.”

Manual vs. Power Systems

- Manual clamps: you crank a screw, slide a bar, or flip a toggle by hand. Good for short runs and setups that change a lot.

- Power clamps: hydraulic, pneumatic, or electric. Hit a switch and they lock down with the same force every time. That’s why high-volume shops use them.

Types of Industrial Clamps

There are plenty of clamp styles, each for a reason. Depends on part shape, material, and the machining you’re doing. Along with these categories, machinists also count on chuck clamps, lathe chucks, and vise jaws for turning and milling.

Mechanical Clamps

Mechanical clamps are the old standbys. You run them by hand. They’re tough, affordable, and found in every shop.

C-Clamps

The classic screw clamp. You spin the screw till the pad pushes down. They grip hard and don’t let go, but they’re slow to adjust. Great when you need force, not speed.

Used For: General-purpose clamping, heavy pressure in low-volume work, holding parts to welding tables

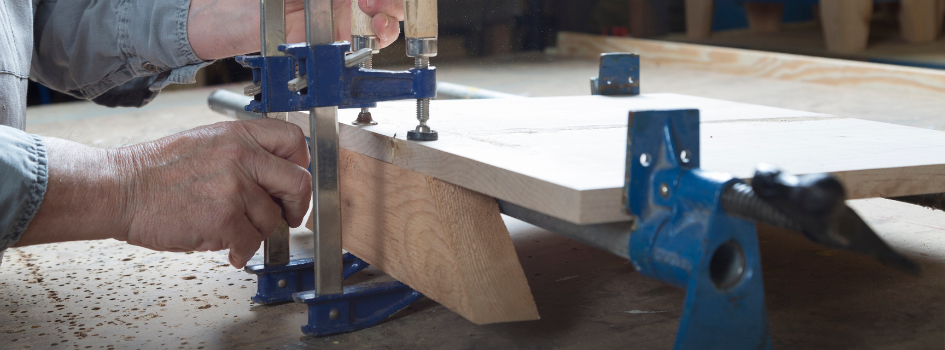

Bar Clamps

Slide the jaw along the bar, then tighten. They reach wider than C-clamps, so they’re common in fab and woodworking. Spread pressure over a larger span.

Used For: Large assemblies, woodworking

Spring Clamps

Squeeze to open, let go to clamp. Quick and handy, but weak compared to screw clamps. Good for light work or holding something in place while you set up.

Used For: Temporary setups, light-duty jobs, quick holding

Toggle Clamps

Flip the handle over-center and it locks solid. Once it snaps, it stays. Used in fixtures and jigs where the same part goes in and out all day.

Used For: Fixtures, repeat setups, medium-duty machining, assembly lines

Hand-Screw Clamps

Wood jaws, two screws. Each screw moves separate, so the jaws can tilt. Lets you grab odd shapes without crushing them. Pressure spreads out across the jaws.

Used For: Irregular shapes, delicate parts, surfaces you don’t want to mark

Hydraulic and Pneumatic Clamps

These do the work for you. Fluid or air powers the clamp so you don’t crank by hand. They save time and give the same force every cycle.

Hydraulic Clamps

Run off a hydraulic pump. They push hard and stay locked. Great for big steel blocks and heavy cuts. They don’t let go until the line pressure drops.

Used For: Heavy machining, large parts, tough materials

Pneumatic Clamps

Air lines make them snap fast. Not as strong as hydraulic, but way quicker. Perfect for production where speed matters more than brute force.

Used For: Automated systems, high-speed runs

Magnetic and Vacuum Clamps

Some parts can’t be held with jaws. That’s when magnets or suction come in.

Magnetic Clamps

Switch them on and magnets hold the part. Only works on ferrous metals. Handy for odd shapes or thin parts with no good spot for a jaw. Electromagnets can be switched off for fast part swaps.

Used For: Ferrous parts, odd shapes, jobs without clamp access

Vacuum Clamps

Suction pulls the part flat against a plate. Works on non-ferrous stuff like aluminum, plastic, or composites. Ideal for thin sheet that bends or gets scratched by regular clamps.

Used For: Non-ferrous materials, fragile parts, thin sheet work

Quick Safety Tips

Clamping systems can slip or break if you don’t check them. A few rules:

- Check clamps before use. Worn screws or bent frames won’t hold.

- Choose clamp sytems with enough capacity for the job.

- Keep fingers out when tightening or popping them loose.

- With hydraulic or pneumatic, bleed the pressure before removing the part.

Learn more from DXP’s expert safety solutions.

Workholding Solutions from DXP

DXP carries manual, hydraulic, pneumatic, magnetic, and vacuum clamps, plus vise jaws, replacement jaws, and chuck clamps. From basic shop gear to production fixtures, DXP can get you set up.

Contact DXP to place an order for industrial clamping systems and components.