Different Types of Conveyors for Your Material Handling Line

You might be surprised to learn how many types of conveyors there actually are. But what are they, and how are they used differently in material handling lines? Let’s find out.

Overview of Industrial Conveyors

Industrial conveyors are mechanical handling systems designed to transport materials efficiently from one point to another within a facility. They operate using a variety of mechanisms (belts, rollers, chains, screws, or air pressure) to move goods horizontally, vertically, or on an incline.

The right conveyor system can manage heavy loads, delicate products, or free-flowing bulk materials with minimal damage risk. In addition, these systems can also be integrated with automation controls for precise handling.

Before selecting a conveyor to ensure optimal performance and ROI, you should conduct a detailed material flow and process analysis.

6 Common Types of Conveyors Used

- Belt Conveyors

- Roller Conveyors

- Chain Conveyors

- Screw Conveyors

- Overhead Conveyors

- Pneumatic Conveyors

It’s helpful to think of conveyors as purpose-built systems. Each design serves specific load capacities, product types, and operational environments.

1. Belt Conveyors

Belt conveyors use a continuous, looped belt made of fabric, rubber, plastic, or metal, stretched over pulleys at each end. The belt is driven by a motorized pulley or drum, providing smooth and continuous motion for transporting materials.

They can be configured for straight-line runs, inclines, declines, or curves. Belt conveyors are highly versatile, handling everything from light packages to bulk aggregates. For harsh environments, belts may be reinforced with steel cords or coated with specialty compounds to resist abrasion, heat, or chemicals.

2. Roller Conveyors

Roller conveyors use a frame-mounted series of cylindrical rollers, which can be unpowered (gravity conveyors) or powered by belts, chains, or motorized rollers.

- Gravity roller conveyors rely on a slight slope and the force of gravity to move items, making them low-energy and low-maintenance.

- Powered roller conveyors use mechanical drive systems to move items at a controlled pace, often in accumulation or sorting applications.

Rollers can be made from steel, aluminum, or polymer, with bearings designed for high load capacities.

3. Chain Conveyors

Chain conveyors consist of one or more strands of looped chain, driven by sprockets at each end. They are engineered for high-strength applications, moving pallets, industrial containers, or parts through heavy manufacturing environments. The chain can be fitted with attachments or slats for supporting specific products.

Their robust construction allows operation in harsher environments such as:

- High-temperature

- Corrosive

- Debris-filled

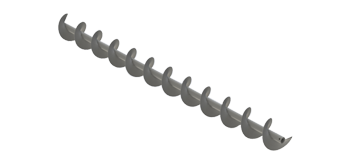

4. Screw Conveyors

Screw conveyors feature a helical screw blade (flighting) mounted on a rotating shaft inside a U-shaped trough or cylindrical casing. As the screw rotates, material is moved forward along the trough. They are ideal for metering or transferring granular, powdered, or semi-solid materials.

Screw conveyors can be inclined, horizontal, or vertical, and are commonly found in agriculture, food processing, and chemical plants. Variable pitch screws allow control over material flow rates.

5. Overhead Conveyors

Overhead conveyors suspend the load from an overhead track, which can be an enclosed track, I-beam, or power-and-free design. Loads are moved via trolleys connected to a continuous chain or cable. They are ideal for maximizing floor space and are widely used in painting, assembly, and storage buffer applications. Overhead systems can include switches, curves, and elevation changes for complex routing.

6. Pneumatic Conveyors

Pneumatic conveyors transport materials through an enclosed pipeline using air pressure (positive displacement) or vacuum (negative pressure). They are best for lightweight, fine, or granular materials and are common in food, pharmaceutical, and plastics industries.

Components include:

- Blowers

- Airlocks

- Filters

- Receivers

Dilute phase systems move materials at high velocity and low pressure, while dense phase systems use low velocity and high pressure for fragile or abrasive products.

Additional Conveyor Types

Beyond the main six categories, there are other specialized conveyor designs used in niche applications:

- Package/Unit Handling Conveyors are designed for moving discrete items like cartons, totes, or trays.

- Tabletop Conveyors are flat, chain-driven systems common in bottling, packaging, and labeling lines.

- Troughed Belt Conveyors are belt systems with a concave profile to contain and move bulk materials.

- Vibratory Conveyors use controlled vibration to move bulk products, often used in food processing and aggregate handling.

- Bulk Drag Conveyors are enclosed systems using paddles or flights attached to chains to drag material through a casing.

- Bulk Elevator Leg Conveyors (also known as bucket elevators) are used for vertical lifting of bulk goods such as grain or aggregates.

- Magnetic Conveyors utilize magnets to move ferrous materials, often used in scrap handling and metal fabrication.

Similar Equipment for Material Handling Lines

In addition to conveyors, facilities often integrate supporting material handling equipment to improve workflow and safety:

- Hoists & cranes are mechanical lifting devices using wire rope, chains, or hoist drums to raise and lower heavy loads vertically, often integrated with bridge or gantry systems for horizontal movement.

- Mezzanines are structural steel platforms providing additional floor levels for storage or processing, supported by columns and engineered to handle specific live loads.

- Pallet jacks are hydraulic lifting tools for moving palletized goods short distances, available in manual or electric-powered designs.

- Carts & hand trucks are wheeled platforms for manual transport of small or irregularly shaped items.

- Scissor lifts are hydraulic or pneumatic platforms that provide vertical elevation for picking, maintenance, or assembly tasks, with safety rails and load ratings for industrial environments.

Expert Tip: A good material handling design often blends conveyor systems with auxiliary equipment to optimize space usage, reduce ergonomic strain, and improve overall workplace safety.

Optimize Your Line with DXP’s Material Handling Solutions

Did you know DXP supplies material handling systems for a variety of industries? We also offer bearings and power transmission products, linear motion products, clutches/brakes, and more to support your complete material handling and production needs.Get in touch today to learn more.