Different Types of Centrifugal Pumps and Their Applications

Centrifugal pumps are currently in use across a vast array of domestic and industrial processes. From supplying the water used in residential buildings to industrial applications like food, beverage, and chemical manufacturing, different types of centrifugal pumps are required to effectively meet pumping requirements.

As reputable centrifugal pump suppliers, DXP has extensive knowledge in this field. This article describes the various pump types and the applications to which they are best suited.

Centrifugal Pumps and How They Work

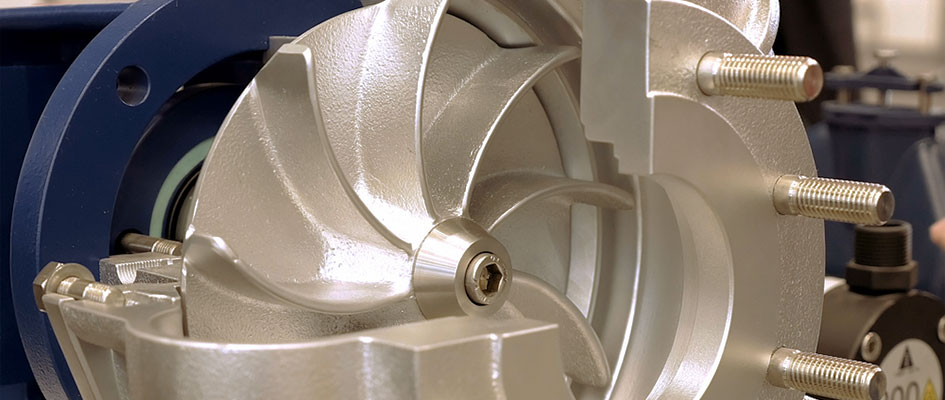

A typical centrifugal pump set up is comprised of one or more impellers attached to a rotary pump shaft. This arrangement provides the energy required to conduct fluid through the pump system and the associated piping.

The impellers turning in sync with the pump shaft converts dynamic mechanical energy from the pump motor into the energy of moving fluids. While most of the energy derived from the motor will be converted to kinetic energy in the pumped fluids, a portion will be channeled as potential energy in fluid pressure calculated against gravity.

Centrifugal Pump Process

The operation cycle begins with the pump directing fluid into its suction ports and directing it onwards to the inlet of its impellers. Rotating impellers then move the pumped liquids along their spinning vanes whilst simultaneously increasing the fluid velocity.

The “charged” fluid then leaves the impeller vanes and is conducted to a diffuser casing or pump volute where high fluid velocity generated from the impeller vanes are converted to high fluid pressure.

Finally, the pressurized fluid is conducted to a discharge port or channeled to the next stage of a multi-stage pump system.

Different Types of Centrifugal Pumps

The major centrifugal pump variations include the following:

Radial vs. Axial Centrifugal Pump

The major distinction between a radial and an axial pump is in their orientation. By design, a radial centrifugal pump permits an outward motion of the liquid channeled through it. The pumped liquid is pressurized and exited through downstream piping.

By comparison, axial pumps generate fluid motion via a lifting effect of their impeller vanes.

ANSI Pumps vs. API Pumps

Many centrifugal pump systems are radial in configuration and are manufactured to meet certain industry standards. Among the most common standards are the American National Standards Institute (ANSI) pumps and American Petroleum Institute (API) pumps.

ANSI pumps are high-quality pumps with a single pump impeller unit that facilitate easier maintenance. ANSI pumps are interchangeable with other similar rated pumps. This type of centrifugal pump is ideal for low rates of fuel flow.

API pumps are manufactured to meet certain industrial dimensions including the presence of a hold-down bolt placement size, and a predetermined pump coupling height. API pumps are typically radial in configuration and are useful in heavy-duty operations in the oil and gas industry.

If you’re looking for quality API and ANSI pump manufacturers, PumpWorks is a DXP subsidiary that provides top-of-the-line industrial pumps.

Single-stage, Two-stage, or Multi-stage

The classification of centrifugal pumps by stage is dependent on the number of impellers present within their setup.

Single-Stage

This pump type houses only one impeller within its casing, making maintenance quite easy. A single-stage centrifugal pump is best suited to low-pressure operations where a large flow rate is maintained.

Two-Stage

A two-stage centrifugal pump possesses dual impellers functioning together to pump the associated process liquids. It is a device best used in medium head applications.

Multi-Stage

Multiple impellers (three or more) are required in this pump system to achieve maximal efficiency. Multistage centrifugal pumps are best for high head applications.

Self-Priming Centrifugal Pumps

Self-priming pumps have a specially designed pump casing that traps liquid to help the pump evacuate air during startup. This design reduces the need for manual priming and improves reliability in intermittent flow conditions. They are commonly used in applications such as wastewater handling, irrigation, and dewatering systems.

Vertical vs. Horizontal Centrifugal Pumps

Vertical centrifugal pumps are ideal for installations where floor space is limited or where flooding risks exist. Their motor and bearings are positioned above the fluid, making them suitable for sump and cooling water applications. Horizontal pumps are easier to install and maintain, often chosen for general industrial use due to their accessibility and stable base-mounted configuration.

Common Industrial Centrifugal Pump Applications

Centrifugal pump uses are common throughout a diverse range of domestic, commercial, and industrial markets. Examples of centrifugal pump applications include but are not limited to:

- Water supply for residential areas

- Fire protection systems

- Sewage/slurry disposal

- Food and beverage manufacturing

- Chemical manufacturing

- Oil and gas industrial operations

DXP Has a Massive Selection of Centrifugal Pumps

At DXP, we provide standards and custom-built pump solutions for a wide range of commercial, and industrial processes including aviation, agriculture, food manufacturing, and oil and gas. With a massive selection of centrifugal pumping systems to choose from, you are guaranteed the best fit for your unique application.

Contact us online today for a quote or to learn more about our state of the art remote pump monitoring systems.