Sand is a nuisance. It chews through valves, erodes pipe walls, clogs separators, and just generally makes a mess of things. But sand is a part of life, especially when… Read more »

Sand is a nuisance. It chews through valves, erodes pipe walls, clogs separators, and just generally makes a mess of things. But sand is a part of life, especially when… Read more »

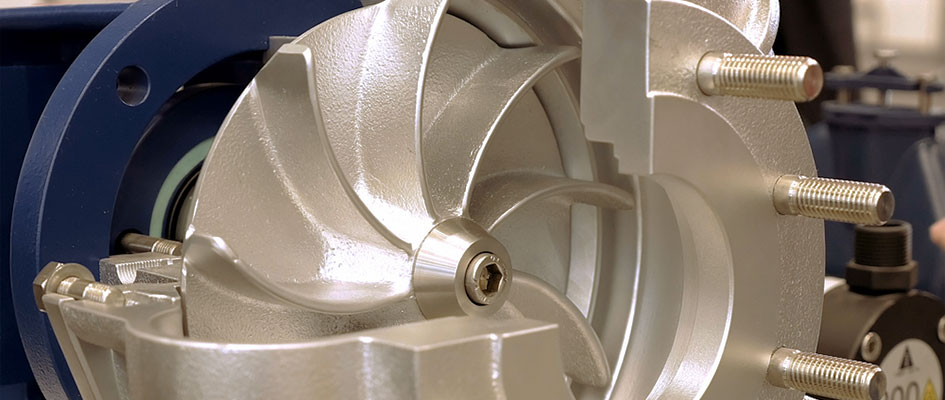

Centrifugal pumps are currently in use across a vast array of domestic and industrial processes. From supplying the water used in residential buildings to industrial applications like food, beverage, and… Read more »

Gas detection isn’t something you think about until it fails…and by then, it’s too late. In industrial settings, gases like hydrogen sulfide or carbon monoxide can’t be seen or smelled,… Read more »

Getting something to move in a straight line and keep doing it day after day takes more than luck. CNC systems, packaging machines, and robotics all rely on linear motion… Read more »

When freezing weather sets in, your equipment can face a major performance challenge. Without the right products, machinery can slow down or even fail. Low temperature lubricants help machines keep… Read more »

Believe it or not, machining precision starts with how a part is held. Workholding clamps are used to keep a workpiece fixed during cutting, welding, or assembly so forces don’t… Read more »

Data center cooling has changed a lot recently because of new technology and AI. As computers get more powerful and produce more heat, old cooling methods don’t work as well…. Read more »

Rotating equipment keeps plants and facilities running, and like any hardworking machine, it eventually needs repair. Think of pumps, compressors, motors, and fans…these all wear down with heavy use. If… Read more »

Protecting your eyes at work is one of the most important steps in creating a safe workplace. Every day, workers face hazards like flying particles, chemical splashes, or intense light… Read more »

Maintenance isn’t only fixing things when they fail. It’s preventing problems, planning resources, and supporting operations without costly interruptions. A strong maintenance management system ties all of this together into… Read more »