Synchronous Belts: Everything You Need to Know

Why do some drives keep perfect timing for years while others slowly drift out of sync? The answer lies in the unique design and behavior of synchronous belts.

What are Synchronous Belts?

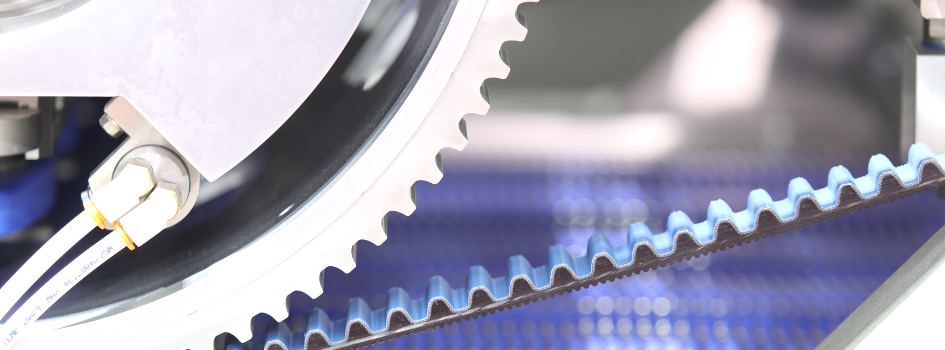

Synchronous belts (often referred to as timing belts) are toothed belts that engage directly with matching pulley grooves. This positive engagement eliminates slip by transmitting power mechanically through tooth engagement, keeping rotating components in exact synchronization.

Synchronous Belts vs. Traditional V-Belts

Traditional V-belts transmit power through friction. To work properly, they rely on correct tension and pulley condition. As belts wear and tension changes, slip can increase and efficiency can drop.

Synchronous belts work differently. The toothed profile locks the belt to the pulley, which eliminates slip and removes the need for frequent retensioning. This makes them easier to manage in applications that run continuously or require consistent motion.

Synchronous belt drives can be stiffer and sometimes louder than V-belts. In return, they tend to hold efficiency and speed accuracy over longer service intervals. For many systems (especially new installations / planned upgrades) that tradeoff is acceptable.

Types of Synchronous Belts by Tooth Profile

One of the first decisions in a synchronous belt drive is tooth profile. Tooth shape affects how load is carried, how the belt wears and how the drive behaves at speed.

1. Trapezoidal Tooth Synchronous Belts

Trapezoidal tooth belts are one of the earliest synchronous belt designs. Common profiles include MXL, XL, L, H and XH. Many older machines were designed around these profiles and still run them today.

The straight-sided teeth seat firmly into the pulley grooves. This design works, but it concentrates load at the tooth root. In higher-torque or higher-speed applications, that stress can limit belt life.

Because of their large installed base, trapezoidal belts are often replaced with the same profile to avoid changing pulleys or reworking the drive. When loads increase or service life becomes an issue, moving to a newer profile is usually worth considering.

Applications:

- Light duty automation

- Legacy machinery with existing pulley setups

- Small conveyors with low shock loads

- Replacement drives on older equipment

2. Curvilinear (HTD) Synchronous Belts

Curvilinear, or HTD (High Torque Drive), belts feature rounded teeth designed to distribute load more evenly across the tooth surface.

This rounded profile reduces stress concentrations at the tooth root and allows torque to be shared across multiple teeth at once. As a result, HTD belts can transmit more power than trapezoidal designs while maintaining consistent engagement under load.

HTD belts also seat more gradually into pulley grooves, which helps reduce vibration and wear during operation.

While HTD belts offer strong performance, they may generate slightly more noise than modified curvilinear profiles in highspeed or precision-driven systems.

HTD synchronous belts are widely used in industrial power transmission, conveyors and automated production equipment. They are frequently specified in conveyor and material handling equipment where reliable torque transmission and long service intervals are priorities.

3. Modified Curvilinear Synchronous Belts

Modified curvilinear profiles such as GT, GT2 and RPP are refinements of the HTD concept. Tooth geometry is adjusted to improve tracking, reduce backlash and increase load sharing.

These belts are often used in compact drives where pulley sizes are small and positioning accuracy matters. They typically run with less vibration and noise than standard HTD belts, particularly in servo-driven systems.

Because of their design, modified curvilinear belts are usually selected for motion-focused applications rather than basic power transmission.

Applications:

- Servo-driven systems

- Robotics

- Precision positioning equipment

Types of Synchronous Belts by Material

Material choice affects how a belt handles its environment as much as how it handles load.

1. Neoprene Synchronous Belts

Neoprene belts are commonly used in general industrial environments. They offer good flexibility, resistance to oil exposure and reliable performance across a wide temperature range.

Applications:

- Industrial machinery

- Material handling systems

- Applications with moderate loads

2. Polyurethane Synchronous Belts

Polyurethane synchronous belts are known for abrasion resistance, chemical stability and clean operation. They are often selected for environments where contamination control matters.

Steel/aramid tensile cords are commonly used in polyurethane belts to support higher loads and longer center distances.

Applications:

- Food and beverage processing

- Packaging equipment

- Clean-room automation

Types of Synchronous Belts by Construction

Construction details also affect how a belt drive performs in service.

1. Reinforced High Torque Belts

High-torque synchronous belts use stronger tensile members and optimized tooth profiles to carry heavy loads in limited space. They are often used to replace chains where lubrication, noise or maintenance is a concern.

2. Double Sided Synchronous Belts

Double-sided belts have teeth on both sides, allowing one belt to drive multiple shafts. These are useful in layouts where space is tight or where opposing rotations are required.

Applications:

- Multi-axis drives

- Complex conveyor layouts

- Packaging machinery with opposing rotations

Contact DXP Today for More Support

DXP supports customers with synchronous belt selection, sourcing and system support. DXP works with trusted manufacturers to supply belt drive components that match real operating demands. DXP also provides related power transmission supplies such as conveyors, bearings, motors and system services.

Questions? Contact DXP to discuss synchronous belt options and supporting components built around your application.

Related Reading: How to Save Energy with Synchronous Belt Drives