Lathe Machine Guide: What is a Lathe and How it Works

A lathe is one of the core machines in any shop that handles shafts, bushings, sleeves, or any part that needs accurate rotation. This guide lays out how the machine works, what it’s used for, and how to use it.

What is a Lathe?

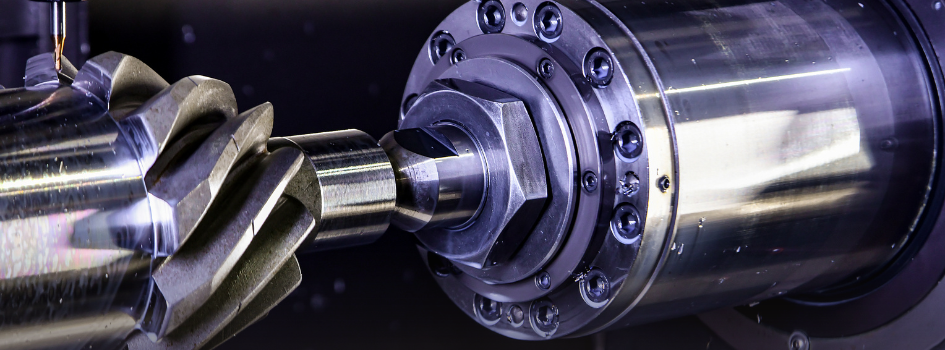

A lathe is a machine tool that rotates a workpiece while a cutting tool shapes it. That rotation is the foundation of the process. The tool stays still, the material spins, and operators remove material in controlled passes. Lathes support metals, plastics, and other machinable materials, giving plant teams a steady way to produce shafts, bushings, couplings and round components.

Most shops rely on two common formats:

- Engine lathes for general-purpose work

- CNC lathes for automated, repeatable runs that need tight accuracy

They all work off the same principle: rotation + controlled feed = material removal

What Does a Lathe Do?

A lathe handles jobs that depend on circular / symmetrical shapes. Some of the most common tasks include:

- Turning: Reducing the outer diameter of a workpiece

- Facing: Squaring off the end of a part

- Boring: Enlarging a hole with precision

- Threading: Cutting external / internal threads

- Parting: Cutting off a finished section

In short, the machine shapes the piece along its axis. If a part needs to be round, centered, or uniform from end to end, the lathe is usually the tool that gets it there.

Types of Lathes

| Lathe Type | Description |

| Bench Lathes | Compact machines mounted on a bench. Suitable for light to medium work with 9 “-13” swings |

| Engine Lathes | Standard shop machines with cast‑iron bases, coolant capability, and foot brakes. Swing typically starts around 13” |

| Miniature Lathes | Small units for very small workpieces. Swings around 3 “-9” |

| Toolroom Lathes | High accuracy machines used for fixtures, gauges, and dies |

| Turret Lathes | Production machines with indexable multi tool turrets for repetitive part cycles |

Metal Lathes vs. Wood Lathes

Metalworking lathes use rigid beds, precision ways, slower spindle speeds, indexed tool posts, and insert based tooling. They’re designed to cut steel, alloys, hard plastics and other materials that require stability under load.

Wood lathes operate at higher spindle speeds and use handheld tools. They are not built for the accuracy, rigidity, or cutting forces required in industrial maintenance or machining work.

Main Parts of a Lathe

While models vary, most share a similar layout:

- Bed: The base that aligns the machine

- Headstock: Houses the spindle and drive system

- Chuck: Holds the workpiece

- Tool post: Secures and positions cutting tools

- Carriage and cross-slide: Move the tool along the workpiece

- Tailstock: Supports long parts with a center or drill bit

Once operators understand these components, setup becomes much quicker and safer.

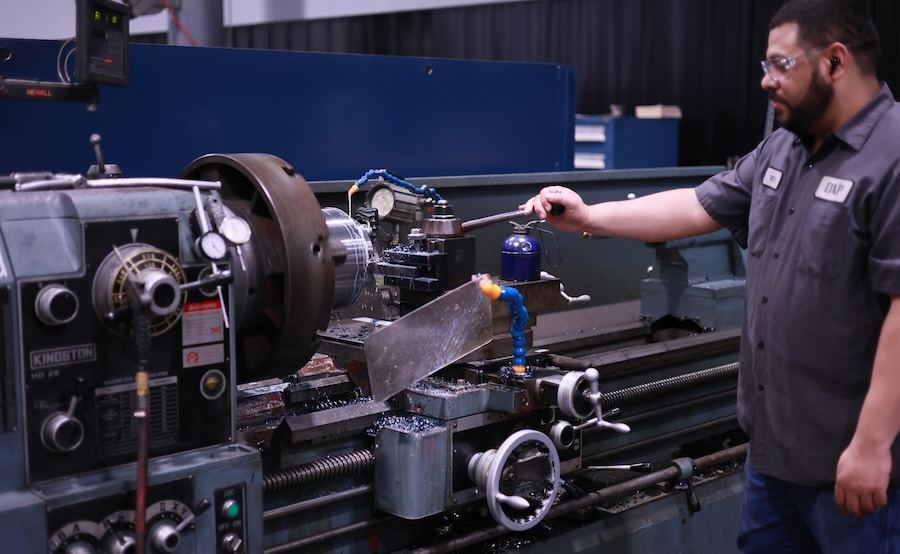

How to Use a Lathe

If you’re training new operators or brushing up on procedures, here’s a simple workflow that applies to most lathe tasks:

- Lubricate the machine. Fill the distribution tank so the spindle bearings, gearbox, shafts, and headstock receive proper oil.

- Stabilize the machine. Mount smaller units on a solid bench or pedestal to prevent vibration.

- Install the workpiece. Clamp it in the chuck and verify runout.

- Set the chuck guard. If equipped, position it correctly before operation.

- Wear PPE. Eye and hearing protection are required. Avoid loose clothing.

- Select the cutting tool. Use roughing, finishing, or threading tools as the job requires.

- Set spindle speed. Larger diameters require lower RPM. Allow the spindle to reach stable speed.

- Make an initial light pass. This confirms tool placement, feed behavior, and chip formation.

- Machine the part. Feed using the carriage and cross‑slide to remove material until the dimension is reached.

- Change tools only when stopped. Power down before adjustments.

- Deburr and measure. Verify dimensions before removing the part.

Remember safety always! Clear chips, shield the rotating area and keep hands and clothing away from the chuck.

Day-to-Day Lathe Tasks

Lathes show up in plants that handle fabrication, repair, or replacement parts. Some frequent applications include:

- Pump shafts

- Roller assemblies

- Fittings and bushings

- Sleeves and couplings

- Motor components

- Custom repair parts

Shops working under tight downtime windows often keep a lathe ready for quick-turn repairs.

Need a Lathe for Your Shop? DXP Can Help

DXP supplies metalworking lathes suited for repair work, component production, and daily machining tasks. Our team assists with selecting machines based on material type, part size, and workload demands. DXP also provides pumping solutions, industrial supplies, safety solutions, and supply chain services if you need expertise in any other area of your business.

Contact a DXP expert today for support on machine selection, setup and service.